Flux Injection Machine (Semi-Auto Matic

A semi-automatic flux injection machine is used to inject a controlled amount of flux into molten metal preventing oxidation, with the operator controlling the start and stop of the process for accurate and efficient application.

Flux Injection Machine (Fully Automatic)

A fully automatic flux injection machine is used to inject a precise, controlled amount of flux into molten metal automatically, preventing oxidation, and increasing process efficiency without manual intervention

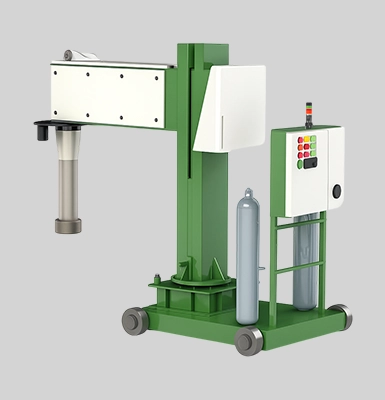

Mobile Deggasing Unit

A mobile degassing unit is a foundry metal treatment system & used to inject Nitrogen/Argon gas into molten aluminum to remove dissolved hydrogen gases from the aluminum melt and reducing the porosity defects from the final casting

Vaccum Testing Machine

A Vacuum Testing Machine is primarily used to detect hydrogen gas present into the aluminum melt by creating a vacuum inside the test chamber and monitoring pressure changes on the indicators

Dosatron

A Dosatron are used for accurately dosing water-based solutions, such as die lubricants or cooling lubricants, into the casting process. They are water-powered and offer precise mixing ratios, ensuring consistent quality and reducing waste in metalworking

Plunger Beads Dispensary System

A Plunger Beads Dispensary System is used to automatically and precisely dispense dry plunger lubricant beads into PDC/HPDC die casting machines, reducing friction, wear, and oxidation while improving the lifespan of plunger tips and sleeves in metal casting operations

Lamotte Calorimeter For Dilution Check

A Lamotte Calorimeter for dilution check is used to accurately measure the concentration of substances in water samples by testing diluted solutions, allowing for precise quantification

Coil Feeder Machine

A coil feeder machine is used in industrial manufacturing processes for the automated feeding of ATB coiled into Aluminum melt